Where Are Extraction Fans Typically Used?

Extraction fans are essential in any environment where clean, breathable air is critical to safety, compliance, and operational efficiency. Whether you’re managing airborne contaminants, odours, or moisture, extraction fans help maintain safe working conditions by removing unwanted air from indoor spaces and replacing it with fresh, clean air.

But where exactly are these fans used—and why are they so vital across different industries?

What Do Extraction Fans Do?

Before diving into specific settings, it helps to understand the role of an extraction fan. These systems are designed to draw out contaminated air—such as fumes, dust, vapours, smoke, and moisture—and either expel it outdoors or direct it through ducting and filtration systems. In doing so, they support:

- Air quality improvement

- Worker health and comfort

- Regulatory compliance

- Protection of machinery and product integrity

Now, let’s explore the key environments where extraction fans are most commonly used.

1. Food and Meat Processing Facilities

Extraction fans are crucial in food production areas to remove steam, odours, airborne grease, and even blood mist. These fans help maintain hygiene by controlling condensation and airborne particles, which can contribute to bacteria growth or product contamination.

In meat processing, where washdowns and high humidity are common, hose-proof and stainless steel extraction fans are used to handle both moisture and rigorous cleaning schedules.

2. Commercial Kitchens

In hospitality settings, extraction fans remove smoke, grease vapour, steam and odours from cooking areas. This protects kitchen staff from respiratory discomfort and reduces fire risk by preventing the build-up of greasy residues.

They’re often installed in canopy hoods or roof-mounted systems and work in conjunction with ducting and filtration units to meet health regulations and building codes.

3. Manufacturing and Workshops

Extraction fans are widely used in manufacturing environments to remove:

- Dust from sanding or grinding

- Welding fumes

- Paint and solvent vapours

- Engine exhaust and smoke

In these settings, exposure to airborne pollutants can have long-term health effects and damage sensitive equipment. Industrial-grade extraction systems help remove these pollutants at the source and ensure safe working conditions.

4. Chemical Handling and Storage Areas

Facilities dealing with hazardous chemicals require specialised extraction fans to safely manage fumes and vapours. This is especially critical in areas where flammable or corrosive substances are stored or used.

In such environments, explosion-proof or corrosion-resistant extraction fans are necessary to meet strict safety standards and avoid the risk of ignition or chemical exposure.

5. Ablution Blocks and Amenities

In large facilities, amenities blocks and change rooms can quickly become uncomfortable without adequate airflow. Extraction fans help remove odours, excess moisture, and airborne bacteria, ensuring these shared spaces remain hygienic and well-ventilated.

6. Spray Booths and Painting Areas

Spray painting and finishing processes release fine particulates and solvent-based vapours that pose serious health risks. Extraction fans fitted with filter systems are used to remove overspray and fumes, keeping both the operator and finished product safe from contamination.

7. Welding Bays and Fabrication Shops

Welding processes generate harmful metal fumes and gases such as ozone and nitrogen oxide. Extraction fans, often paired with localised hoods or ducted arms, are used to extract welding fumes directly from the source, protecting workers and reducing environmental exposure.

8. Pharmaceutical and Laboratory Environments

In highly controlled environments like labs and cleanrooms, extraction fans help maintain sterile conditions by removing airborne particles and chemicals. These systems are often part of a broader HVAC or containment setup and are carefully engineered to meet strict air quality standards.

9. Cold Storage and Washdown Zones

In environments that require high-pressure hose-downs or operate in wet conditions, extraction fans help prevent mould, corrosion, and structural damage caused by excess humidity. Models used here are typically hose-proof, IP-rated, and made from stainless steel for durability and hygiene.

Closing Thoughts

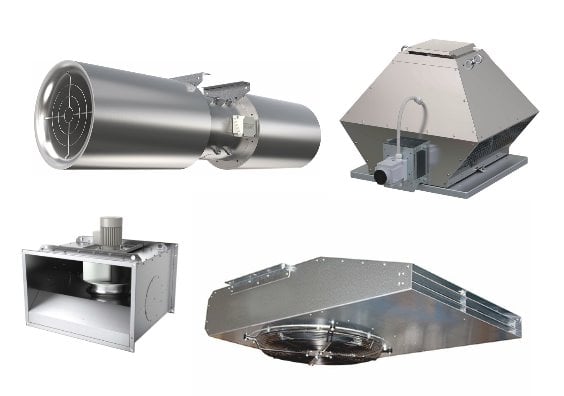

From removing toxic fumes in workshops to managing steam and odours in food processing plants, extraction fans are a critical component of industrial and commercial ventilation systems. They don’t just make workplaces more comfortable—they protect workers, prevent damage, and ensure businesses remain compliant with Australian safety standards.

Fanquip offers a wide range of rugged, high-performance extraction fans made to handle the toughest Australian conditions. Whether you need wall-mounted, roof-mounted, ducted, or hose-down rated solutions, we can help you find the right fan for your environment.